Our steel cutting capacities mean we can process steel from a 0.0° square cut to a 45° and 60° mitre cut. Our beam line capacity includes steel plasma and saw cutting, coping, notching and mitre cutting and can handle varying cutting lengths, degrees and thicknesses to cover most steel cutting requirements in galvanised and mild steel processing.

Quality Service

in Steel

Steel Cutting

Structural steel cutting

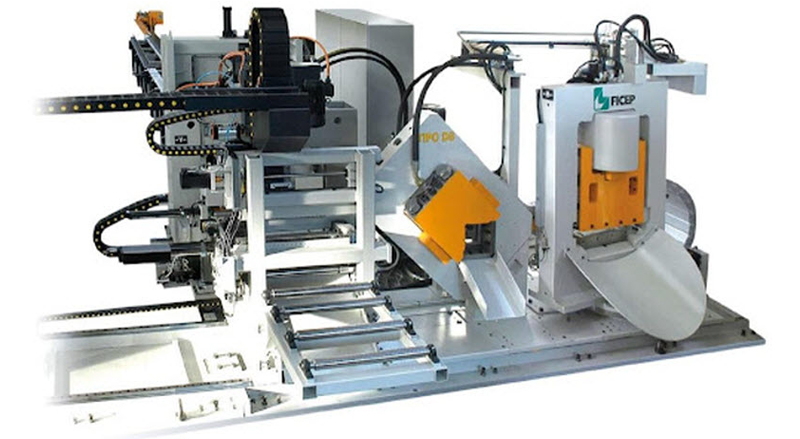

Structural steel cutting and processing require large, competent machines operated by qualified steel specialists. We have invested in internationally acclaimed, market leading machinery developed by discerning engineers to adequately process large form structural steel.

We use the FICEP 1101 DZB Beam Line, an Everising HW500/900 twin column bandsaw and the HGG which has the capacity to cut 1200mm wide.

Quality steel cutting performance

Our multi-functional Ficep 1101 DZB beam line can drill and cut steel with incredible accuracy.

Cutting capacities

- At 0.0° square cut

- Width = 80mm to 1015mm

- Height = 45mm to 450mm

- Mitre cut at +/- 45°

- Width = 80mm to 650mm

- Height = 45mm to 450mm

- Mitre cut at +/- 60°

- Width = 80mm to 650mm

- Height = 45mm to 450mm

Drilling capacities

- Holes up to 40mm in diameter

Everising HW500/900

Our Everising HW500/900 twin-column bandsaw offers a maximum cutting capacity at 0° of up to 900mm wide x 500mm high. Our Everising machines can be numerically controlled in programmed length and mitre cutting of up to 60° one way and 45° in the other.

Machine capacity at specific angles (150 min width)

- 0° 900mm wide x 500mm high/520mm round

- 45° 580mm wide x 500mm high/500mm round

- 60° 375mm wide x 500mm high/375mm round

Hydmech

At Brice Metals, we use Hydmech’s V-series saws.

These saws are robust, efficient and capable of high-performance processing. They are heavy duty, flexible vertical tilt frame saws that cut two-way mitres. They are semi-automatic and our skilled steel experts operate this impressive series.

V-25

The V-25 Hydmech heavy-duty machine comes with a two-stage gearbox and motor that offer a large variation of band speeds and optional mist lubrication for optimal steel processing capacity.

V-25APC

The V-25APC has a programmable, hydraulically powered guide arm attached to the saw column that can adjust to the material’s height when mitring. This machine is touch screen control programmable for up to 1000 jobs with 20 in the queue. Its 60” bar feed can index up to 60” or 120”, and the shuttle carriage can move on linear rails using an advanced rack and pinion servo drive to ensure optimal blade performance in steel cutting and processing.

Capacity:

- 635mm wide x 760mm high

- 60° left and right

- 1.5” blade

- 10 HP blade drive

Cold saw cutting

Our semi-automatic cold saw cutting capabilities enable us to precisely cut heavy-duty metal. We can process steel profiles, solids and tubes with our cold saw. Its superior performance and reliability guarantee a burr-free, milled finish.

Its quick action mitring potential is supported by a fully integrated coolant system and industrial lead-screw unit with a smart actuation motor that automates the cutting cycle.

Looking for quality steel cutting or cold saw cutting?

Look no further than our industry-leading machines that offer steel cutting capabilities guaranteed to suit your project needs. We will work with you from start to finish, so can be sure that we cut your steel right the first time, so get in touch today.

Call Us

Call Us